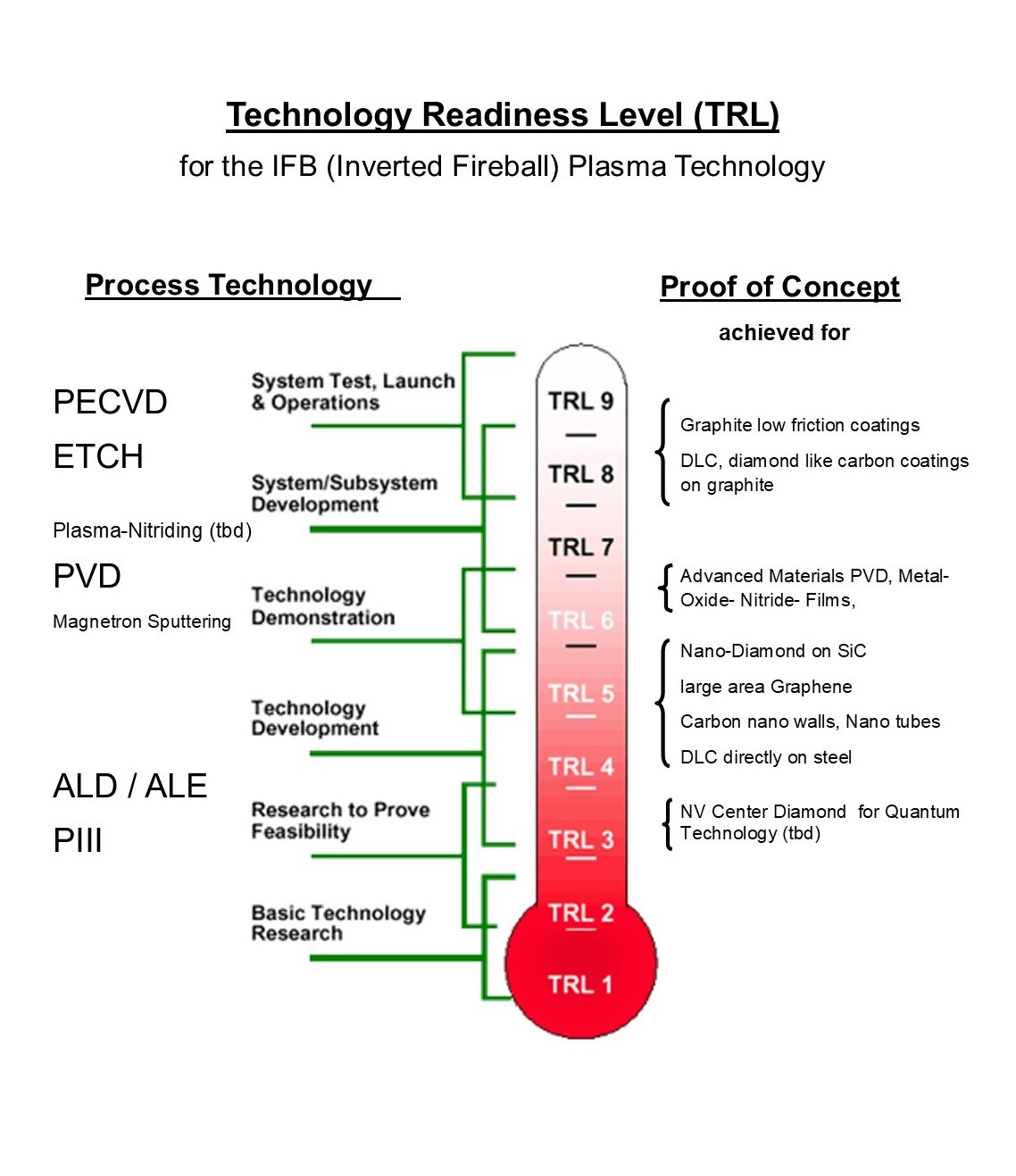

„THE TECHNOLOGY“ for future developments !

Our grid enhanced technology (get) plasma increases the plasma density in your surface modification processes, no matter if you want to coat, etch, sputter or clean your substrates. The plasma is concentrated around the work piece, which leads to significantly higher process/energy efficiency, faster deposition/etching rates and improves system productivity.

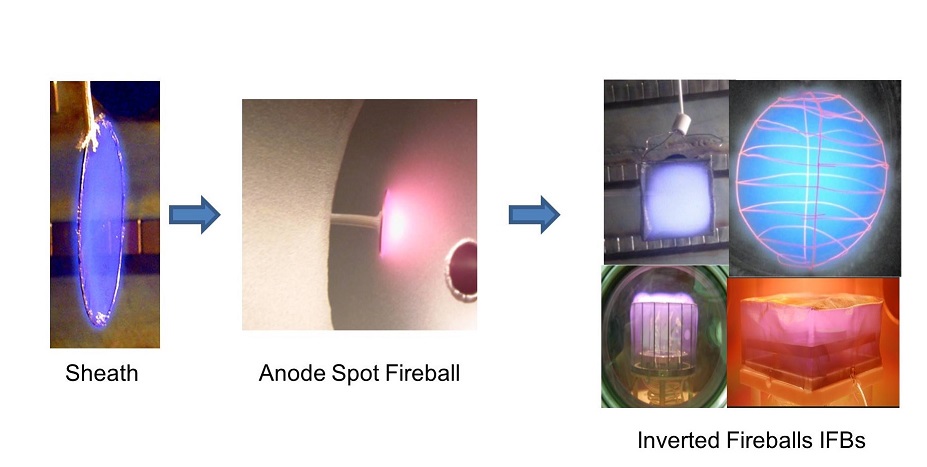

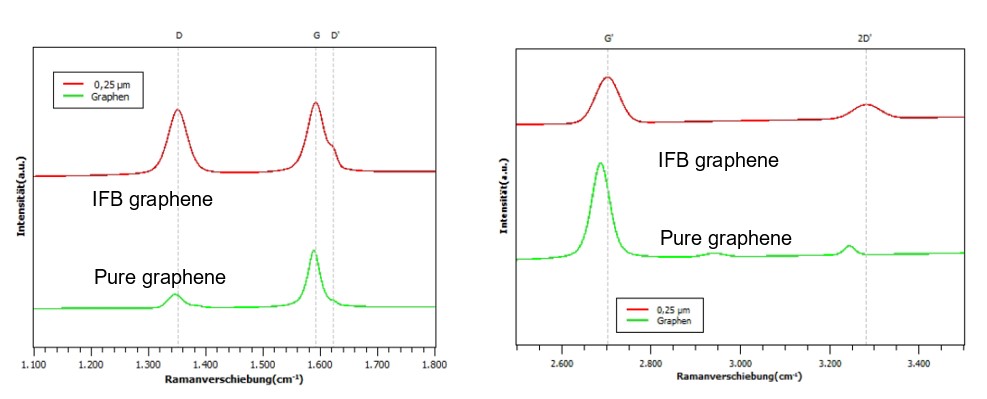

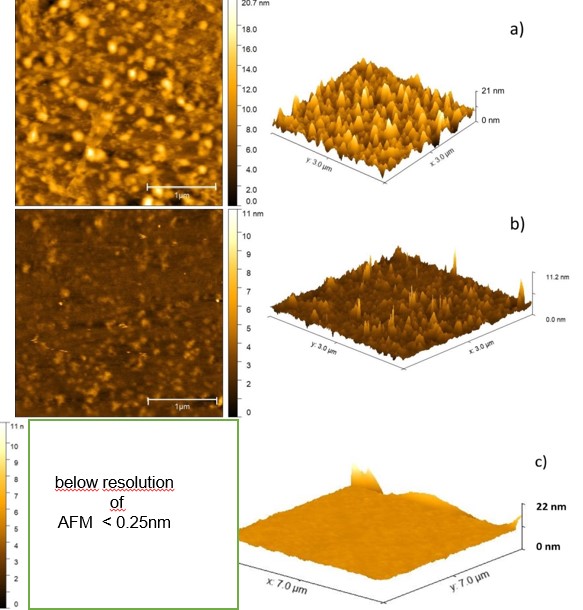

| Basics of the get-plasma process The get-plasma process is based on so-called inverted fireballs (IFBs), which form inside a grid electrode that is enclosed by a Debye sheath – it is basically an evolution of the double layer that forms in front of a positively biased electrode inside an existing plasma. |

As the electrons go through the grid they induce additional ionisation processes and, hence, increase the plasma density. At the same time an equipotential is formed around the grid, which traps the electrons inside the mesh. This dense plasma can be utilized to coat, etch, activate or sputter large surfaces at a fast rate.

Advantages of get-plasma Technology:

- Overall energy and process efficiency

- It can be integrated into already existing low-pressure plasma systems

- Long term process stability

- Large area plasma treatment is feasible

- High growth rates are achievable

- An excellent tool for carbon film deposition on various surfaces

- Less machine down time

- The promising bridge technology for graphene developments

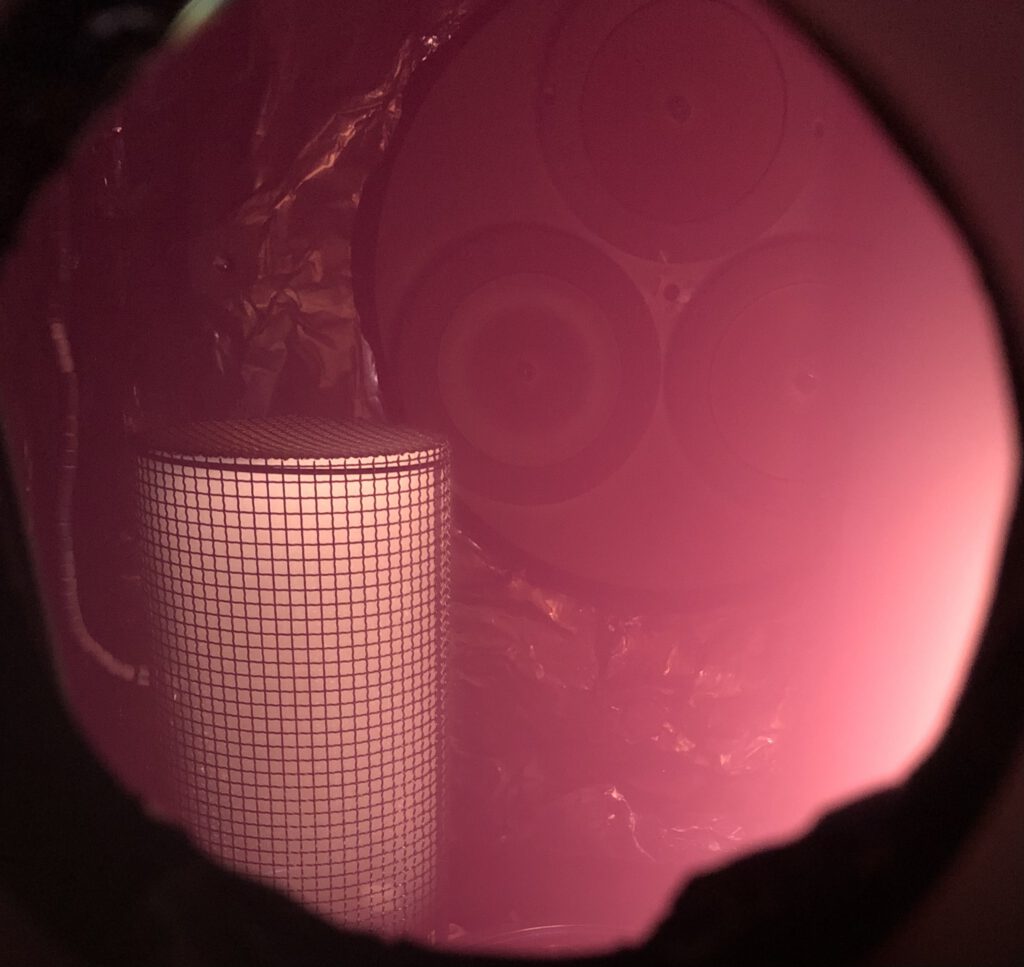

NEW: The first IFB obtained via MAGNETRON SPUTTERING

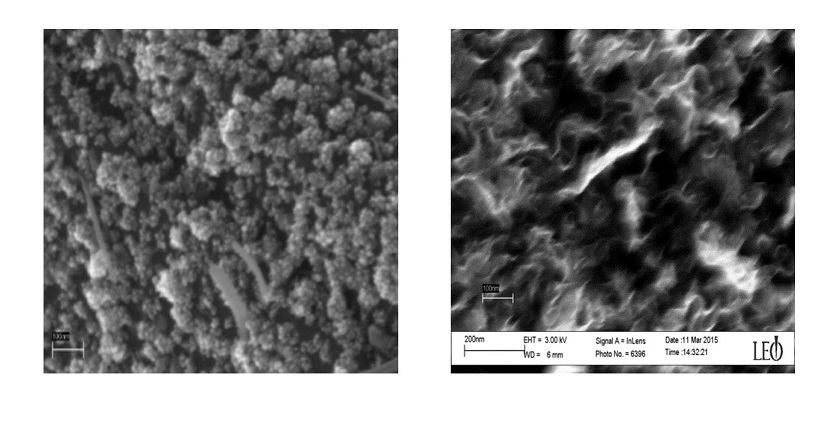

Examples of carbon coatings obtained with get-plasma:

Contact Us

You have any questions regarding our get-plasma?

You are interested in investing in our business?

You want to collaborate with us?

Send us an email to info@get-plasma.tech or Eichenhofer@get-plasma.tech or Gruenwald@get-plasma.tech.

Links to scientific papers

1Measurement of inverted n-hexane fireball properties with a Multipole Resonance Probe

2Application and limitations of inverted fireballs in a magnetron sputter device

4Diamond Like Carbon Deposition by Inverted Fireballs

5PECVD of carbon by inverted fireballs: From sputtering, bias enhanced nucleation to deposition

6Inverted fireball deposition of carbon films with extremely low surface roughness (submitted to Carbon Letters)

7Graphenabscheidung auf Kupfer mittels invertiertem Feuerball, Bachelor Thesis, University of Graz 2017 (only in German and not online)